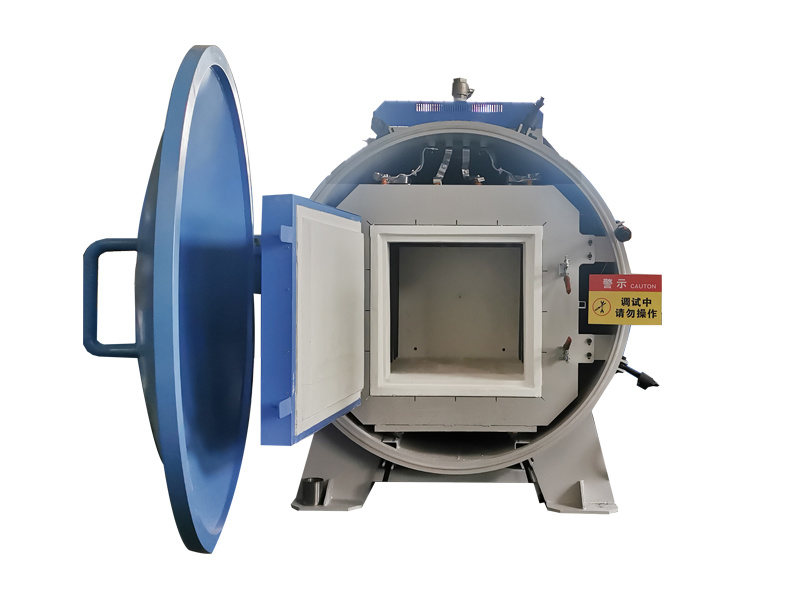

1700℃ Large Capacity High Vacuum Heat Treatment Furnace PV L216/17

PV L216/17

Classification:

TMax 1700°C,Carbon steel double water-cooling housing,1800# ceramic fiber chamber,high-quality new type MoSi2 rod,Yudian PID controller,programmable 30 segments.With diffusion vacuum pump, Max10-3mbar,work under inert gas atmosphere.

Telephone:

Attachments:

- Overview

- Technical

- Video

-

- Commodity name: 1700℃ Large Capacity High Vacuum Heat Treatment Furnace PV L216/17

- Commodity ID: PV L216/17

- 产品概述: TMax 1700°C,Carbon steel double water-cooling housing,1800# ceramic fiber chamber,high-quality new type MoSi2 rod,Yudian PID controller,programmable 30 segments.With diffusion vacuum pump, Max10-3mbar,work under inert gas atmosphere.

<p>Work in inert atmosphere such as vacuum and N2</p> <p>Multi-set gas inlet and outlet,gases mixed precisely</p> <p>With diffusion vacuum pump,vacuum valve, Max10-3mbar</p>

Product Overview

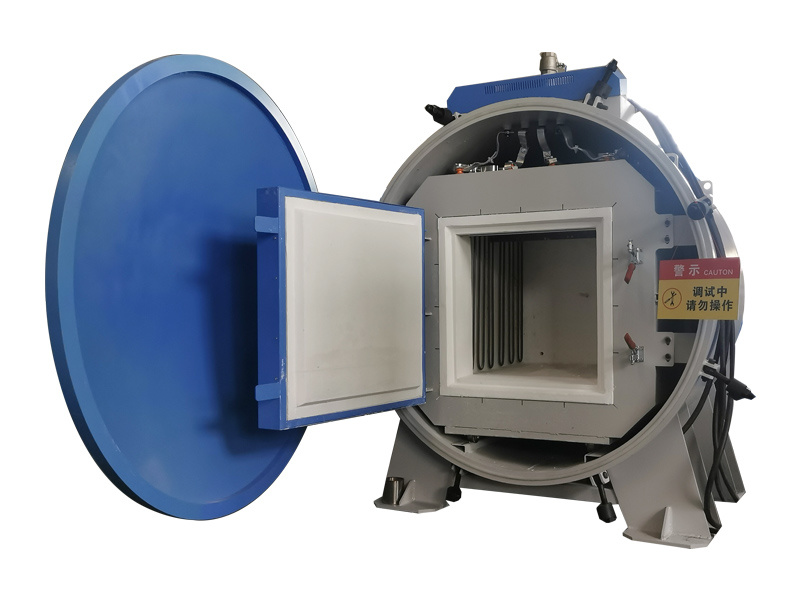

PV L216/17 is a Box type vacuum heat treatment furnace,designed for sintering materials under vacuum up to 1600°C,chamber capacity is 216L.Carbon steel double water-cooling housing.1800# ceramic fiber chamber.With diffusion vacuum pump, Max10-3mbar,work under inert gas atmosphere such as nitrogen.Heating element uses high-quality new type MoSi2 rod.Yudian PID controller,programmable 30 segments, high temperature control accuracy.Multi-set air inlet and outlet equipped with pressure gauge and stainless steel ball valve.Vacuum furnaces provide the perfect heat treatment environment for a variety of procedures in many laboratories, providing the controlled temperature and atmosphere required for specific projects. Ideal for sintering new materials in vacuum or gas atmosphere, calcination process or pyrolysis.

Main Features

- TMax 1600°C

- Carbon steel double housing,furnace surface water cooling circulation,reduce surface temperature

- 1800# polycrystalline ceramic fiber raw materials,CNC carved,high temperature resistance,efficient energy saving

- Pressure gauge and stainless steel ball valve,multi-set air inlet and outlet,gases can be mixed precisely

- Double furnace door design,good sealing effect and less heat loss

- Vacuum pump optional, Max 10-3mbar

- Work in inert atmospheres such as vacuum and nitrogen

- Heating rate 0℃-10℃/min adjustable

- MoSi2 rod heated,both sids heating,uniform temperature field

- Type B Thermocouple,long service life

- Smart 30-segment programmable automatic temperature control,high temperature control accuracy

- Power off, over-temperature, thermocouple breaking and burnout protection

- Good performance and energy saving effect

- CE certification

Product Details

1700℃ Large Capacity High Vacuum Heat Treatment Furnace

- PV L216/17 Large Capacity High Vacuum Heat Treatment Furnace consists of five parts: furnace body,gas mixing system,vacuum system,water-cooling circulation system and temperature control system.

- Furnace surface is pickled and phosphated, environmental friendly electrostatic powder sprayed and baked,anti-oxidation and corrosion-resistant.Furnace surface water cooling circulation,the surface temperature Rt+45℃.

- Siemens electrical components, long service life.

- Export quality, ISO,CE certified.

1700℃ Large Capacity High Vacuum Heat Treatment Furnace,Chamber

- Chamber lining uses 1800# high alumina ceramic fiber,CNC carved.Square chamber,chamber walls tight coupling.

- U-shape new type MoSi2 rod,both sides heating,uniform temperature field,TMax 1700°C.(In air)

- B-type thermocouple,long service life

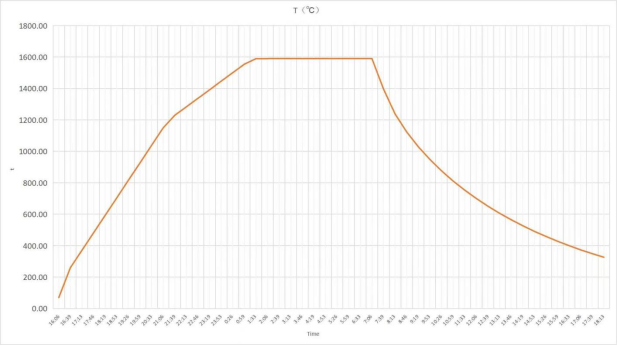

Heating programs for 1700°C Vacuum Furnace

- Yudian PID controller,programmable 30 segments, heating rate 1-10C/min freely adjusted

- Good thermal insualtion, natural cooling, cooling down gently

- 7" touchscreen panel is optional, heating programs can be showed timely, and downloaded

-

Detail Technical Specifications

Model No. PV L216/17 Chamber size (DxWxH) D600xW600xH600mm /24x24x24″ Capacity 216L Structure Outer shell/Insulation chamber/Furnace door(double design)/Temperature control system/Vacuum system/Water-cooling system Power supply 45KW AC380V 50/60Hz Phase 3 phases Working temperature TMax 1700℃(3092℉)(In air)

Continuously 1600℃(2912℉)Temperature uniformity +/-5℃ Temperature range Rt-1700℃ Temperature controller Yudian PID controller

Auto-tune function

Programmable 30 segments

Temperature accuracy +/- 1°CHeating elements U-shape MoSi2 rod (12pcs)

Heating rate Max:10℃/min

Recommend:1-8℃/minThermocouple type B Furnace shell Carbon steel double water-cooling housing Chamber material 1800# Polycrystalline ceramic fiber raw material,CNC carved,high temperature resistance,efficient energy saving Electric components Schneider or Siemens maker air switch,AC contactor,Solid state relay etc. Safety measures Power off, over-temperature, thermocouple breaking and burnout protection Atmosphere performance H2, Ar, N2 etc.

Not to exceed 0.03 MPa/150torr/3psiVacuum performance Max 10-3mbar Gas supplying system Individual set float flow gas control system (Gas mixing device Optional)

Multi-set air inlet and outlet,G1/4" pagoda gas nozzle

Gas flow 60-600ml/minCompliance CE, ISO Warranty 18-month warranty with lifetime technical support Standard packing list Furnace body/Gas system/High temperature gloves/Crucible tongs/Fire door/Two additional MoSi2 rod/Manual book Optional accessories Vacuum pump/Mass flow mixing system/Gas Detection System/Chiller Shipment information Weight: 1950 kgs

W1800xL2360xH2250mmAfter-sales 1. Consumables such as heating elements, thermocouple etc. are not covered by the warranty.

2. Damage caused by corrosive gases or acid gases is not covered by the warranty.

3. Free spareparts supplying including freight cost within warrantyWarnings 1. Please don't inject toxic or explosive gases without necessary safety controls and supervision measures.

2. Before introducing reducing or flammable and explosive gases, please replace furnace gas. Nitrogen can be used as the replacement gas.

3. Small cracks may appear on the surface over extended use. Normal,repaire with aluminum oxide coating,hose barb connection.Similar model comparison

Model.No PV L3/17 PV L8/17 PV L12/17 PV L36/17 Inner size(DxWxH) 150x150x150mm 200x200x200mm 300x200x200mm 400x300x300mm Capacity 3 L 8 L 12 L 36 L Power supply 4 KW 6 KW 6 KW 13 KW Furnace dimensions(LxWxH) 1060x760x1610mm 1060x760x1610mm 1100x810x1660mm 1100x920x1750mm Weight 390 KGS 450 KGS 536 KGS 660 KGS -

Key words:

1700℃ Vacuum Furnace

Large Capacity Furnace

High Vacuum Furnace

Heat Treatment Furnace

Previous Page

Qualification Honor

FAQ

A

A

A

A

A

A

Powerful engineer team make free customization based on your technical reqeusts

Fast delivery: 7-25 working days

Special discount: Universities OR Research institutes could apply special discount $100-$500 based on contract amount Excellent after-sales service: Free parts supplied including courrier cost to door; local distributor maintaining; 7/24 hours on line

OEM/ODM is acceptable

Certificates: UDEM CE, ECM CE, TUV EC, ATEX CE, SGS, ISO

online message

If you are interested in cooperation, please contact us immediately and we will give you feedback as soon as possible!

Service Hotline

Related Products

1700℃ 12L High Vacuum Heat Treatment Furnace

TMax 1700°C,Carbon steel double water-cooling housing,1800# Polycrystalline ceramic fiber chamber,high-quality new type MoSi2 rod heated,Yudian PID controller,programmable 30 segments.With diffusion vacuum pump, Max10-5mbar.

Work in inert atmosphere such us vacuum and N2

With diffusion vacuum pump, Max10-5mbar

Multi-set air inlet and outlet,gases mixed precisely