1600°C CVD High Temperature Vacuum Tube Furnace

PT D60/300/16

Classification:

CE certified CVD high temperature vacuum tube furnace, single zone, benchtop, non-opening and closing. Widely used in heat treatment under vacuum or atmosphere environment, CVD experiments etc.

Telephone:

Attachments:

- Overview

- Technical

- Video

-

- Commodity name: 1600°C CVD High Temperature Vacuum Tube Furnace

- Commodity ID: PT D60/300/16

- 产品概述: CE certified CVD high temperature vacuum tube furnace, single zone, benchtop, non-opening and closing. Widely used in heat treatment under vacuum or atmosphere environment, CVD experiments etc.

<p>Single-channel gas supplying unit,flow rate adjustable</p> <p>Vacuum system,Max vacuum degree 50Pa</p> <p>For CVD experiments,semiconductors etc.</p>

Product Overview

PT D60/300/16 CVD high temperature vacuum tube furnace, single temperature zone, benchtop, non-opening and closing, suitable for tube diameter 60mm, TMax 1600℃. Dual carbon steel outer shell, high temperature and corrosion resistance. High alumina ceramic fiber chamber, MoSi2 rods heated, uniform temperature field. The length of the heating zone is 300mm. Furnace tube is made of high-purity alumina ceramic corundum tube with quick-opening flange. Equipped with single-channel gas supplying unit and vacuum supplying system, max vacuum degree up to 50Pa. Intelligent PID temperature controller, programmable 30 segments, +/- 1 °C accuracy. This furnace is widely used in heat treatment under vacuum or atmosphere environment, CVD experiments, as well as semiconductors, nanomaterials, carbon fiber, graphene and other new materials, new process areas.

Main features

- Tmax 1600°C

- Single temperature zone, benchtop, non-opening and closing, CVD vacuum tube furnace

- Dual steel structure, anti-oxidation and corrosion resistance, with built-in cooling fan, reduce surface temperature

- High alumina ceramic fiber chamber, tight coupling

- High-purity alumina ceramic corundum tube with quick-opening sealing flanges

- Powerful MoSi2 heating elemets ensure uniform temperature

- Digital PID controller with programmable 30 segments

- Dual flanges support provides better sealing and longer tube life

- Equipped with a single-channel gas supplying unit, flow rate 60-600ml/min adjustable

- Equip vacuum supplying system, max vacuum degree can reach 50Pa

- Long life type B thermocouple

- CE certified, standard

Product Details

1600°C CVD High Temperature Vacuum Tube Furnace

- The 1600°C CVD High Temperature Vacuum Tube Furnace is mainly composed of four parts: furnace body, gas supplying system, vacuum supplying system, and temperature control system

- The furnace outer steel shell is processed with pickling and phosphating, environment powder coating on the surface, corrosion and oxidation resistance, built-in cooling fan, surface temperature Rt+45℃

- Exquisite appearance, ISO, CE compliance

1600°C CVD High Temperature Vacuum Tube Furnace

- High alumina ceramic fiber chamber, CNC engraving, chamber walls tight coupling, U type MoSi2 heater, Tmax 1600°C

- Heating length 300mm, suitable for high-purity alumina ceramic corundum tube diameter 60mm. High-purity alumina ceramic corundum processing tube, temperature resistance up to 1600℃.

- B type thermocouple

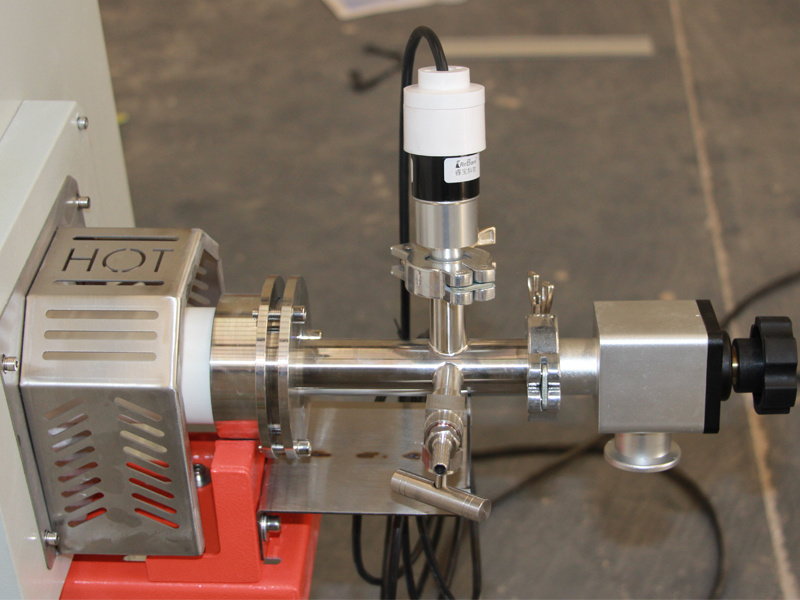

Quick opening flange, furnace tube supports, 1/4" pagoda gas nozzle

- One end of the tube is equipped with 304 stainless steel sealing quick-opening flange, convenient for loading and unloading of materials

- The other endof the tube is equipped with K25 quick-opening flange connected with the vacuum pump through the corrugated pipe

- Vacuum value can be controlled by point control or area control, with automatic start and stop, and the vacuum degree can reach up to 50Pa

Individual set of single channel gas supplying device

- The 1200C-1700C laboratory tube furnaces are all equipped with a single-channel gas supply device, reserved inlet and outlet ports, pressure gauge

- Double ferrule joints; gas float flowmeter, the flow rate is adjustable ranges 60-600ml/min

- Available gases: N2, Ar, H2, CO etc

NOTE:When filling reducing gases, check valves, one-way valves, exhaust gas treatment systems, etc. need to be configured

1600°C CVD High Temperature Vacuum Tube Furnace, Vacuum supplying system

- Vacuum supplying system equipped with vacuum pump, pipeline and valve

- Adopt famous brand pump model VRD-8, pumping speed 2L/S, maximum vacuum degree can reach 50Pa

- Equipped with high-quality oil mist filter, filter oil mist and avoid oil mist pollution effectively

1600°C CVD High Temperature Vacuum Tube Furnace, Temperature control system

- Temperature control system consists of ammeter, voltmeter, temperature control instrument, and buttons

- Intelligent PID temperature controller with 30-segment programs, accuracy of ±1°C

- Power off, over-temperature, thermocouple breaking and burnout protection

- Temperature self-tuning function

- With 485 communication interface (Optional)

-

Detail Technical Specifications

Model No. PT D60/300/16 Structure Dual steel shell, ceramic chamber, furnace tube, tube supports, gas supplying system, vacuum supplying system, temperature control system etc Heating length 300mm /12″ Temp. uniformity ±5℃,heating length 130mm Tube size OD60mm Tube material High-purity alumina ceramic corundum tube Power supply 5KW AC220V 50/60Hz

Phase Single phase Working temperature Tmax:1600℃

Continuous working temperature:1500℃Sealing flange SS304 quick-opening sealing flange, K25 quick-opening flange connected with the vacuum pump Atmosphere performance Available gases: Ar N2 H2 etc. Vacuum performance Max vacuum level could reach to 50Pa Gas supplying system Equips an individual set of single channel gas supplying device with gas inlet&outlet;

Gas flowing rate:60-600ml/minTemperature controller Yudian PID controller

Auto-tune function

Programmable 30 segments

Temperature accuracy +/- 1°CHeating elements MoSi2 heating elements Heating rate Max heating rate:15℃/min

recommended heating rate:10℃/minThermocouple type B Furnace shell Dual carbon steel shell Chamber material High alumina ceramic fiber Electric components Schneider maker air switch, AC contactor, SSR Relay etc Safety measures Over heating, thermocouple breaking alarm and protection Compliance CE, ISO Warranty 18 months quality warranty with lifetime technical support (excluded consumable parts such as quartz tube, thermocouple etc) Standard packing list Tube furnace; furnace tube, sealing flanges, gas tube, furnace hook, thermal gloves, manual book etc Shipment information Gross weight:238 kgs

packing size:W640xL1170xH980mmOptional accessories Vacuum pump unit; MFC system Warning 1. The processing tube pressure should be lower 0.02MPa

2. Gas source should equip the pressure reducing valve

3. Before filling reduction gases like H2, should pump the air out of the tube

4. When filling gases from gas inlet in the tube, should make sure the gas outlet valve openSimilar model comparison

Model No. PT D40/300/17 PT D60/300/17 PT D100/300/17 Heating zone length 300mm 300mm 300mm Tube size OD40xL900mm OD60xL900mm OD100xL900mm Power 3 KW 5 KW 5 KW Furnace overall size(LxWxH) 1130x600x960mm 1170x640x980mm 1190x660x980mm Weight 185 KGS 238 KGS 276 KGS -

Key words:

High Temperature Tube Furnace

1600C Tube Furnace

CVD Tube Furnace

Vacuum Tube Furnace

Single Zone Tube Furnace

Qualification Honor

FAQ

A

A

A

A

A

A

Powerful engineer team make free customization based on your technical reqeusts

Fast delivery: 7-25 working days

Special discount: Universities OR Research institutes could apply special discount $100-$500 based on contract amount Excellent after-sales service: Free parts supplied including courrier cost to door; local distributor maintaining; 7/24 hours on line

OEM/ODM is acceptable

Certificates: UDEM CE, ECM CE, TUV EC, ATEX CE, SGS, ISO

online message

If you are interested in cooperation, please contact us immediately and we will give you feedback as soon as possible!

Service Hotline

Related Products