1700C Single Zone Rotary Tube Furnace with flange and 80mm Alumina Tube - PTR D80/300/17

PTR D80/300/17

Classification:

PTR D80/300/17 is a single zone 80mm dia. rotary tube furnace with 1800 Grade MoSi2 Heating Elements, this rotary tube furnace is particularly suitable for particulate materials heat treatment processes in which continuously flowing at high temperatures.

Telephone:

Attachments:

- Overview

- Technical

- Video

-

- Commodity name: 1700C Single Zone Rotary Tube Furnace with flange and 80mm Alumina Tube - PTR D80/300/17

- Commodity ID: PTR D80/300/17

- 产品概述: PTR D80/300/17 is a single zone 80mm dia. rotary tube furnace with 1800 Grade MoSi2 Heating Elements, this rotary tube furnace is particularly suitable for particulate materials heat treatment processes in which continuously flowing at high temperatures.

<p>Rotary tube furnace,rotating speed adjustable</p> <p>MoSi2 heating elements, Quick-open flange</p> <p>Individual set of gas supplying device</p>

Product Overview

PTR D80/300/17 is a 1700℃ single zone, benchtop rotary tube furnace. Rotating speed 1-8rpm freely adjusted, allowing the powdery or granular samples inside to fully and uniformly react with in atmospheres or vacuum sintering. Double-layer carbon steel shell structure. 1800# high aluminum ceramic insulation. 99.5% alumina tube, quick-opening sealing flanges with 1/4" gas pipe adaptor, MoSi2 heating elements, programmable 30 segments digital controller with an accuracy of +/-1C.It's suitable for production of pulverized Iron ore, minaral testing, Jewelry, such as precious gemstones (N2, Co2 ,Ar, O2, H2 More), heating for debonding, cables, optical fibers.

Main Features

- Tmax 1700°C

- Single Zone, benchtop, rotary tube furnace

- Dual steel structure, minium heat loss

- Individual set of single-channel gas supplying system

- Rotating speed 1-8rpm

- Fiber-insulated chamber for maximum temperature stability and uniformity

- Powerful MoSi2 heating elemets ensure uniform temperature

- Digital PID controller with programmable 30 segments

- 99.5% Alumina content processing tube with SS304 sealing flanges with 1/4" gas pipe adaptor

- Dual flanges support provides better sealing and longer tube life

- Long life type B thermocouple

- CE certified, standard

Product Details

1700°C SINGLE ZONE ROTARY TUBE FURNACE WITH FLANGES AND ALUMINA TUBE

- The 1700°C single zone rotary tube furnace is mainly composed of five parts: furnace body, furnace tube, flange sealing accessories, gas supplying system and temperature control system

- The furnace outer steel shell is processed with pickling and phosphating, environment powder coating on the surface, corrosion and oxidation resistance, built-in cooling fan, surface temperature Rt+45℃

- Exquisite appearance, ISO, CE compliance

1700°C SINGLE ZONE HIGH TEMPERATURE ROTARY TUBE FURNACE CHAMBER

- High alumina ceramic insulation, CNC engraving, chamber walls coupling tightly, U type MoSi2 heater, temperature resistance up to 1800C

- Heating length 300mm, suitable for alumina tube diameter 40-80mm. High alumina processing tube, temperature resistance up to 1700℃,The critical part of the heating zone inside the furnace tube is equipped with the ceramic tube plug, which can effectively prevent heat from escaping and reduce heat loss

- B type thermocouple

NOTE:Chamber structure is only for reference, take the real design as standard

Quick opening flange with rotary joint, 1/4" pagoda gas nozzle

- Equipped with SS304 quick-opening flange accessories for materials fast loading and unloading, sealed with high-temperature resistant fluorine rubber sealing rings

- The air inlet and outlet adopts G1/4-inch pagoda air nozzle, which can be connected to a PTFE pipe with an outer diameter of 8mm. Max vacuum can reach 10*-7torr

- Equipped with adjustable flange brackets to ensure safe and stable operation of the furnace tube

Individual set of single channel gas supplying device

- The 1200C-1700C laboratory tube furnaces are all equipped with a single-channel gas supply device

- Double ferrule joints; gas float flowmeter, the flow rate is adjustable ranges 60-600ml/min

- Available gases: N2, Ar, H2, CO etc

NOTE:When filling reducing gases, check valves, one-way valves, exhaust gas treatment systems, etc. need to be configured

CONTROL PANEL FOR 1700°C SINGEL ZONE HIGH TEMPERATURE ROTARY TUBE FURNACE

- Integrated design with temp controller, Ammeter, voltmeter, function buttons on panel

- Intelligent PID temperature controller with 30-segment programs, accuracy of ±1°C

- Power off, over-temperature, thermocouple breaking and burnout protection

- Temperature self-tuning function

- With 485 communication interface (Optional)

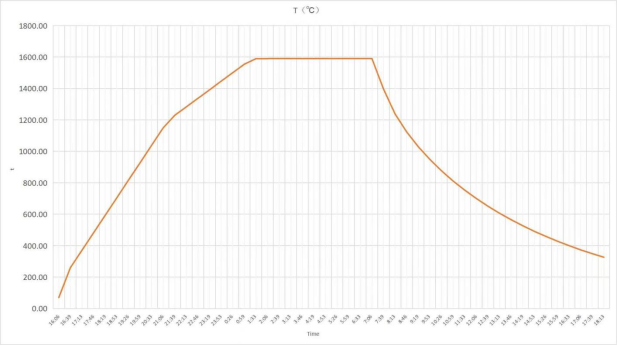

HEATING PROGRAMS FOR 1700°C SINGLE ZONE ROTARY TUBE FURNACE

- Programmable 30 segments, heating rate 1-10C/min freely adjusted

- Good thermal insualtion, natural cooling, cooling down gently

- 7" touchscreen panel is optional, heating programs can be showed timely, and downloaded

-

Detail Technical Specifications

Model No. PTR D80/300/17 Structure Dual steel shell, ceramic chamber, alumina tube, tube supports, rotary system, atmosphere controlled gas supplying system, temperature controlling system etc Heating length 300mm /12″ Temp. uniformity ±5℃,heating length 130mm Tube size OD80mm, ID70mm, length 900mm Tube material High Alumina Content processing tube 99.6% Power supply 6KW AC220V 50/60Hz Phase Single Working temperature Tmax:1700℃(3092℉)

Continuous working temperature:1600℃(2912℉)Sealing flange SS304 quick-opening sealing flanges with needle valve and pressure gauge Atmosphere performance Available gases: Ar N2 H2 etc Vacuum performance Max vacuum level could reach to 10-5torr provided with molecular pump unit Gas supplying system Equips an individual set of single channel gas supplying device with gas inlet&outlet;

Gas flowing rate:60-600ml/minRotary system Material heated evenly

Motor drived processing tube, rotary speed:1-8rmp/minTemperature controller Yudian PID controller

Auto-tune function

Programmable 30 segments

Temperature accuracy +/- 1°CHeating elements MoSi2 heating elements Heating rate Max heating rate:10℃/min

recommended heating rate:1-8℃/minThermocouple type B Furnace shell Dual carbon steel shell Chamber material 1800# Ceramic alumina insulation Electric components Schneider maker air switch, AC contactor, SSR Relay etc Safety measures Over heating, thermocouple breaking alarm and protection Compliance CE,ISO Warranty 18 months quality warranty with lifetime technical support (excluded consumable parts such as quartz tube, thermocouple etc) Standard packing list Tube furnace; alumina tube, sealing flanges, gas tube, furnace hook, thermal gloves, manual book etc Shipment information Gross weight:200kgs

W800xL2650xH1530mm

Optional accessories Vacuum pump unit; MFC system Warning 1. The processing tube pressure should be lower 0.02MPa

2. Gas source should equip the pressure reducing valve

3. Before filling reduction gases like H2, should pump the air out of the tubeSimilar model comparison

Model No. PTR D40/300/17 PTR D60/300/17 PTR D100/300/17 Heating length 300mm 300mm 300mm Tube size OD40xL1000mm OD60xL1000mm OD100xL1000mm Power supply 1.8 KW 2.8 KW 3.0 KW Weight 150 KGS 170 KGS 250 KGS

Key words:

Rotary Tube Furnace

1700C Tube Furnace

Single Zone Tube Furnace

Alumina Tube Furnace

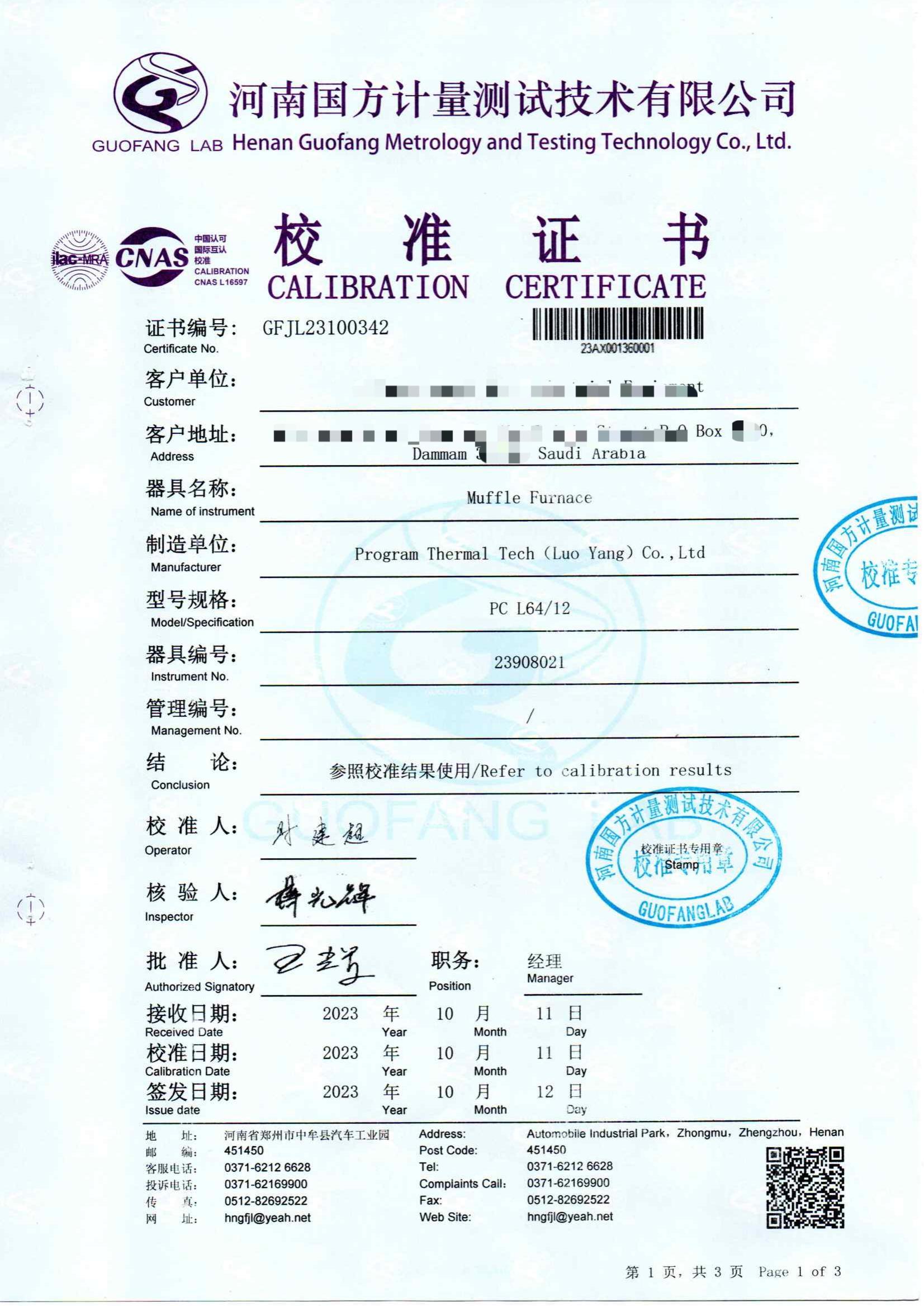

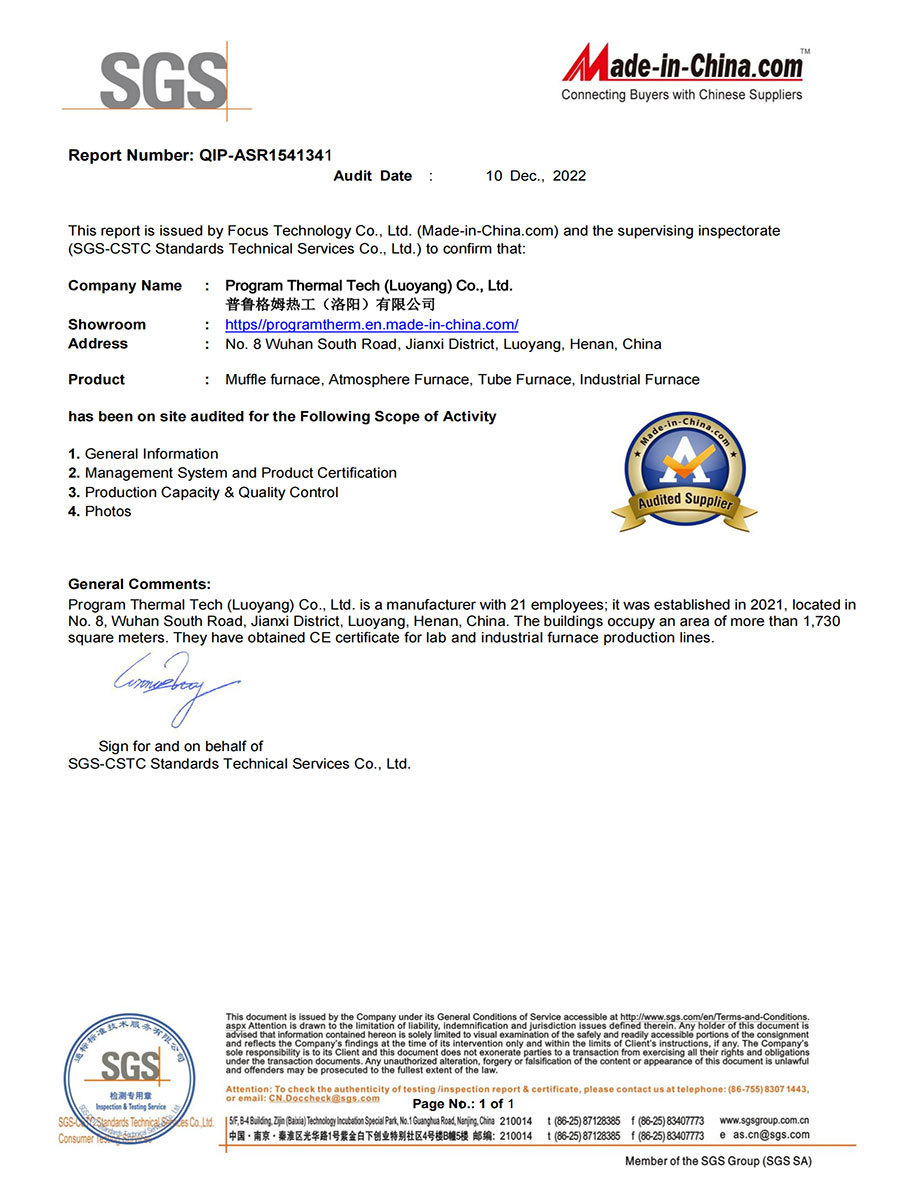

Qualification Honor

FAQ

A

A

A

A

A

A

Powerful engineer team make free customization based on your technical reqeusts

Fast delivery: 7-25 working days

Special discount: Universities OR Research institutes could apply special discount $100-$500 based on contract amount Excellent after-sales service: Free parts supplied including courrier cost to door; local distributor maintaining; 7/24 hours on line

OEM/ODM is acceptable

Certificates: UDEM CE, ECM CE, TUV EC, ATEX CE, SGS, ISO

online message

If you are interested in cooperation, please contact us immediately and we will give you feedback as soon as possible!

Service Hotline

Related Products

1700°C High Temperature Tube Furnace with Alumina tube and vacuum flanges OD80mm

PT D80/300/17 is a 80mm (3") high temperature tube furnace with MoSi2 Rods heating elements. It is widely used in material & chemical labs to sinter various types of new material samples under vacuum or other gas conditions up to 1700C.

Dual flanges support provides better sealing

Max vacuum level could reach to 10E-5 torr

Microprocessor-based self-tuning PID controller

1700C High Temperature 3 Zones Lab CVD Vacuum Tube Furnace With OD60mm Alumina Tube

PTC D60/600/17/3 is a CE certified OD60mm 3 zones tube furnace with complete gas supplying system.The tube furnace can create the various thermal gradient by adjusting three zones temperature.

CVD,Multi-zone,zones controlled independently

Alumina tube with water cooling quick-opening flanges

Multi gas inlet and outlets, available for gas mixing

1700C CVD 3-zone Vacuum Tube Furnace with MFC Gas Mixer and Molecular Pump Unit

PT D80/1500/17 is a three-zone CVD high vacuum OD80 alumina tube furnace, heating length 1500mm. Equips with a molecular vacuum pump unit, 3-channel digital MFC gas mixing system, water cooling system, tube diameter 80mm, max temeprature up to 1700 degree C.

CVD, 3-zone, high vacuum tube furnace

MFC controlled 3-channel gas mixer

Molecular pump unit, max vacuum level 10-5 torr

1600℃ Chlorine Gas Rotary Tube Furnace with OD170mm Recrystallized SiC Tube

PTR D170/900/17 is a rotating tube furnace under Chlorine gas atmosphere, features dual layer air-tight pressurized shell with water cooling system , equips material feeding box, discharging box, gas inlet and outlet, Rotary& tilting, OD170mm Recrystallized SiC tube with MoSi2 heating elements, max temperature up to 1600 degree C.

Quartz transparent observation window

Feeding&discharging box design,water cooling flanges

PLC controlled 7" touchscreen panel