Application areas

In the chemical field, it's often used to synthesize high-purity materials, melt tests and catalytic reactions. For example, when preparing catalysts, calcining, activating, reducing or oxidizing the required materials can improve the activity and stability of the catalyst. It can also be used for heating and drying certain production processes in the chemical industry, and to manufacture materials required for high-temperature and high-pressure reactors, boiling dryers and other equipment. Electric heating furnaces play an important role in the chemical industry and provide important technical support for the production and research and development of chemicals.

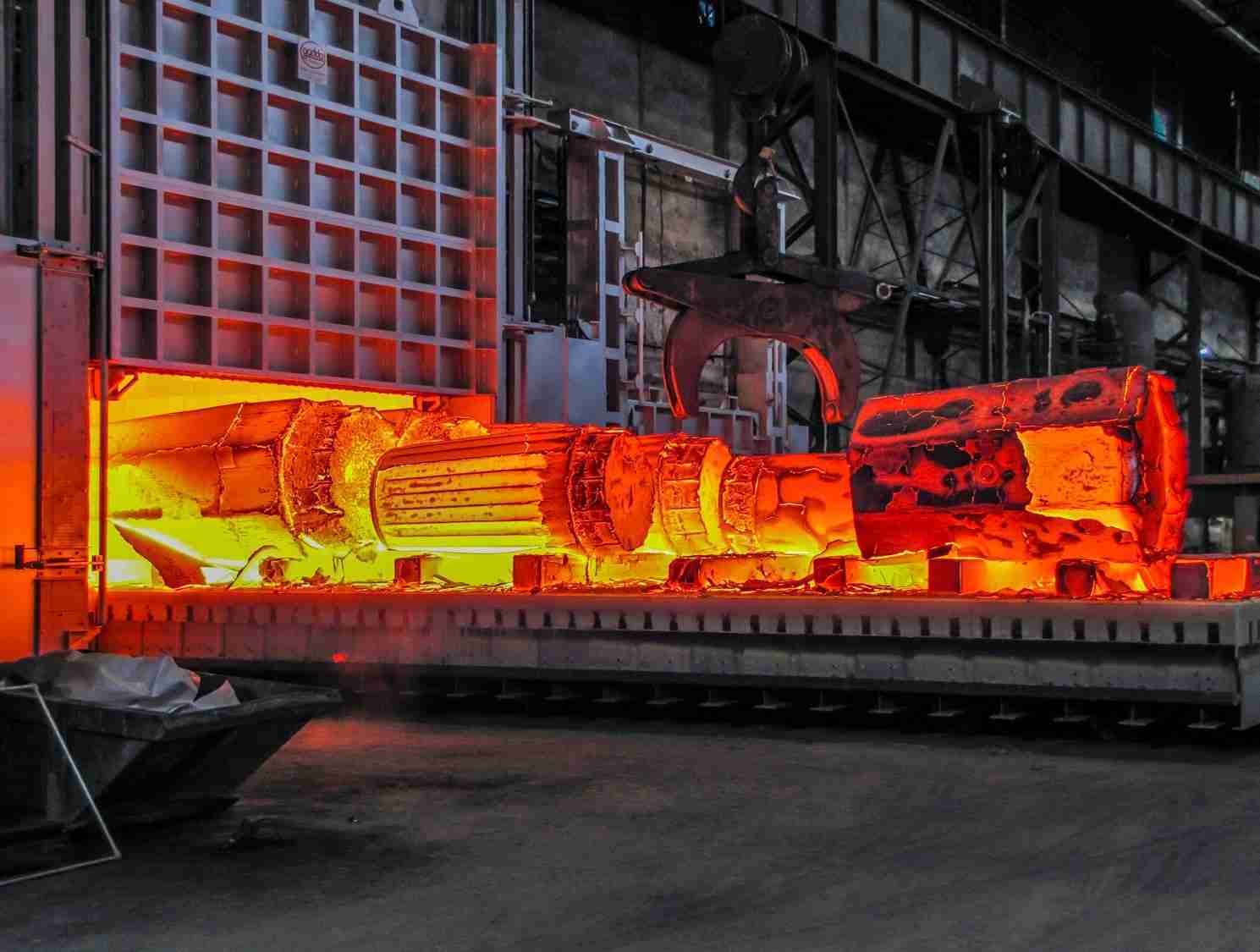

In the aerospace field, it's mainly used for the refining and processing of high-temperature scrapped metal parts, as well as the direct production of materials such as steel, zirconium, titanium, magnesium, etc.; it can simulate the study of reverse carburization and photochemical effects in space; it can perform heat treatments such as quenching and tempering on aircraft engines and their components to improve their service life and durability, and at the same time it can detect whether the quality of components meets the standards.

Suitable for heating and melting various metals, used in metal heating, melting, annealing, quenching and other processes, as well as manufacturing heat-resistant alloys and other high-temperature metal products. It can quickly heat metal at high temperatures and maintain a constant temperature to meet different process requirements.

Mainly used for heat treatment tests of materials, such as crystal recrystallization, annealing, homogenization, stress relief and other processes. These processes can change the structure and properties of materials and improve the strength, toughness, corrosion resistance and so on of materials.

In the chemical field, it's often used to synthesize high-purity materials, melt tests and catalytic reactions. For example, when preparing catalysts, calcining, activating, reducing or oxidizing the required materials can improve the activity and stability of the catalyst. It can also be used for heating and drying certain production processes in the chemical industry, and to manufacture materials required for high-temperature and high-pressure reactors, boiling dryers and other equipment. Electric heating furnaces play an important role in the chemical industry and provide important technical support for the production and research and development of chemicals.

In the aerospace field, it's mainly used for the refining and processing of high-temperature scrapped metal parts, as well as the direct production of materials such as steel, zirconium, titanium, magnesium, etc.; it can simulate the study of reverse carburization and photochemical effects in space; it can perform heat treatments such as quenching and tempering on aircraft engines and their components to improve their service life and durability, and at the same time it can detect whether the quality of components meets the standards.

Suitable for heating and melting various metals, used in metal heating, melting, annealing, quenching and other processes, as well as manufacturing heat-resistant alloys and other high-temperature metal products. It can quickly heat metal at high temperatures and maintain a constant temperature to meet different process requirements.

Mainly used for heat treatment tests of materials, such as crystal recrystallization, annealing, homogenization, stress relief and other processes. These processes can change the structure and properties of materials and improve the strength, toughness, corrosion resistance and so on of materials.