Aerospace

1. Material heat treatment: In the aerospace field, many metals and composite materials need to undergo specific heat treatment processes to improve their physical and chemical properties. Electric heating furnaces can provide precise temperature control and a uniform heating environment to ensure that the material achieves the desired performance during the heat treatment process.

2. Engine component manufacturing: Aircraft engines are one of the core components in the aerospace field, and electric heating furnaces are required in their manufacturing process. For example, in the manufacturing process of engine turbine blades, electric heating furnaces can be used for high-temperature solution treatment and aging treatment to improve the high temperature resistance and mechanical properties of the blades.

3. Aircraft metal structural parts processing: In the field of aerospace, many aircraft metal structural parts need to be processed and formed after high temperature heating. Electric heating furnaces can provide a stable high temperature environment to ensure that metal structural parts maintain a constant temperature during processing, thereby obtaining high-quality finished products.

4. Composite material processing and repair: Composite materials are widely used in the aerospace field to reduce weight and improve performance. Electric heating furnaces can be used for hot pressing and heat curing of composite materials, as well as repair and reinforcement of composite materials.

5. Aerospace experiments and tests: In the field of aerospace, many experiments and tests need to be carried out in a high temperature environment. Electric heating furnaces can provide a stable high temperature environment to simulate the working environment of aerospace vehicles under extreme conditions, so as to test their performance and reliability.

Related Products

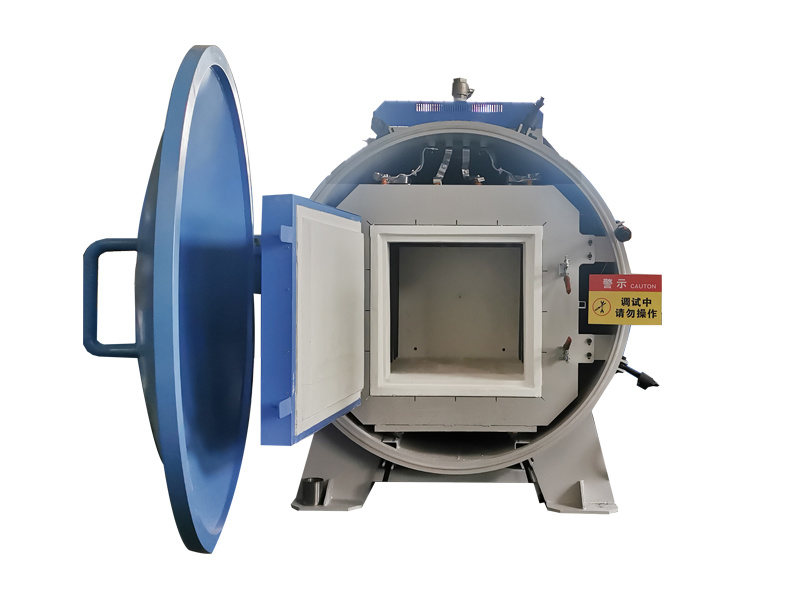

1700℃ Large Capacity High Vacuum Heat Treatment Furnace PV L216/17

TMax 1700°C,Carbon steel double water-cooling housing,1800# ceramic fiber chamber,high-quality new type MoSi2 rod,Yudian PID controller,programmable 30 segments.With diffusion vacuum pump, Max10-3mbar,work under inert gas atmosphere.

Work in inert atmosphere such as vacuum and N2

Multi-set gas inlet and outlet,gases mixed precisely

With diffusion vacuum pump,vacuum valve, Max10-3mbar

1200℃ Electric Bogie Hearth Furnace

Automatic electric bogie furnace,JM26# high alumina brick chamber,HRE alloy coil wire heated,5 sides heating,Shimaden PID controller,Dual zones independent control.

Automatic lift door with hydraulic workstation

Bottom trolley automatically drives in and out

Electric exhaust system for optimal ventilation and rapid cooling

Loading capacity 1 ton-5 tons

1700℃ Ceramic Sintering High Temperature Electric Lifting Furnace 64L

Stable electric bottom loading system,carbon steel double air-cooling housing,round chamber,chamber lining uses 1850# Polycrystalline ceramic fiber raw material.U-shape MoSi2 rod heated,4 sides heating,Yudian PID controller.

Three-stage alumina tiles bottom tray

Bottom electric lifting, loading and unloading freely

7" touch screen controller with USB adapter