New energy

1. Production and processing of solar panels: In the production process of solar panels, high-temperature electric heating furnaces are required for certain process treatments, such as sintering and heat treatment. These processes can ensure the quality and performance of solar panels and improve their photoelectric conversion efficiency and service life.

2. Production of lithium-ion batteries: Lithium-ion batteries are indispensable energy components in electronic products such as electric vehicles and smart phones. In the production process of lithium-ion batteries, electric heating furnaces can be used for battery drying, heat treatment, formation and other processes to ensure the performance and safety of the batteries.

3. Biomass energy conversion: Biomass energy is a renewable energy source, and electric heating furnaces are also needed in its conversion and utilization. For example, in the process of biomass gasification and biomass pyrolysis, electric heating furnaces can provide a stable high-temperature environment to promote the efficient conversion of biomass energy.

4. Research and development of new energy materials: With the continuous development of new energy technologies, the research and development of new energy materials has become increasingly important. Electric heating furnaces can be used in the synthesis, preparation and performance testing of new energy materials, providing strong support for the research and development of new energy materials.

Related Products

1200C Large Vertical Rotary Single zone Tube Furnace with OD300mm Metal Tube

PTR D300/600/12 is a customized vertical rotary tube furnace, mainly for calcining ceramic oxide and graphite powder.

310SS stainless steel tube with built-in stirring blade

Loading volume 10L,Rotating speed 0.1-5rpm

SS304 sealing flange with gas inlet and outlet

1700C CVD 3-zone Vacuum Tube Furnace with MFC Gas Mixer and Molecular Pump Unit

PT D80/1500/17 is a three-zone CVD high vacuum OD80 alumina tube furnace, heating length 1500mm. Equips with a molecular vacuum pump unit, 3-channel digital MFC gas mixing system, water cooling system, tube diameter 80mm, max temeprature up to 1700 degree C.

CVD, 3-zone, high vacuum tube furnace

MFC controlled 3-channel gas mixer

Molecular pump unit, max vacuum level 10-5 torr

1700℃ 12L High Vacuum Heat Treatment Furnace

TMax 1700°C,Carbon steel double water-cooling housing,1800# Polycrystalline ceramic fiber chamber,high-quality new type MoSi2 rod heated,Yudian PID controller,programmable 30 segments.With diffusion vacuum pump, Max10-5mbar.

Work in inert atmosphere such us vacuum and N2

With diffusion vacuum pump, Max10-5mbar

Multi-set air inlet and outlet,gases mixed precisely

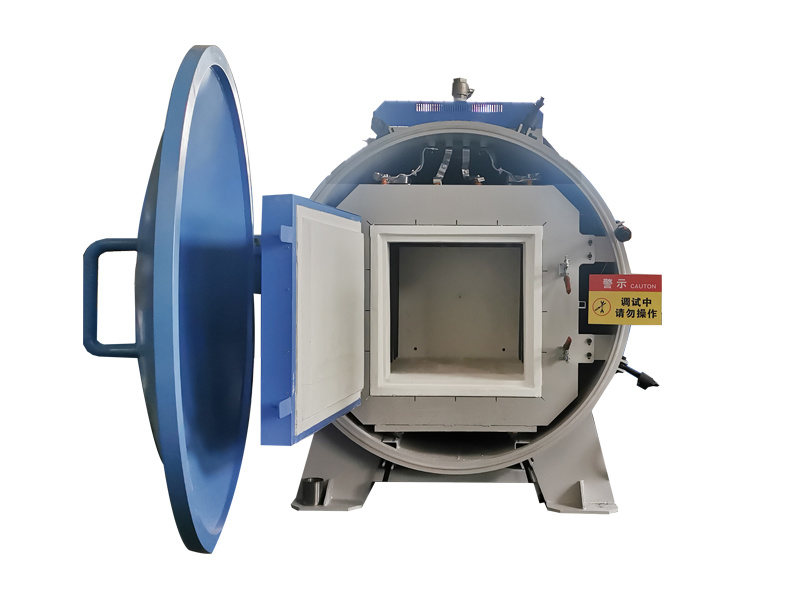

1700℃ Large Capacity High Vacuum Heat Treatment Furnace PV L216/17

TMax 1700°C,Carbon steel double water-cooling housing,1800# ceramic fiber chamber,high-quality new type MoSi2 rod,Yudian PID controller,programmable 30 segments.With diffusion vacuum pump, Max10-3mbar,work under inert gas atmosphere.

Work in inert atmosphere such as vacuum and N2

Multi-set gas inlet and outlet,gases mixed precisely

With diffusion vacuum pump,vacuum valve, Max10-3mbar